experts in energy balancing solutions

your partner in integrated spring systems, wearable devices and human interactive mechanisms.

intespring:

making things weightless

InteSpring is an engineering consultancy firm specializing in the development of systems that balance force and gravity using springs to enhance the performance of humans and devices alike.

Our 4-phase modular consulting approach covers the whole development process from idea to certified product. InteSpring works efficiently and fast due to our small team of experts, strong network of suppliers, in-house prototyping capabilities, as well as numerous technologies already at hand to be adapted at a moment’s notice.

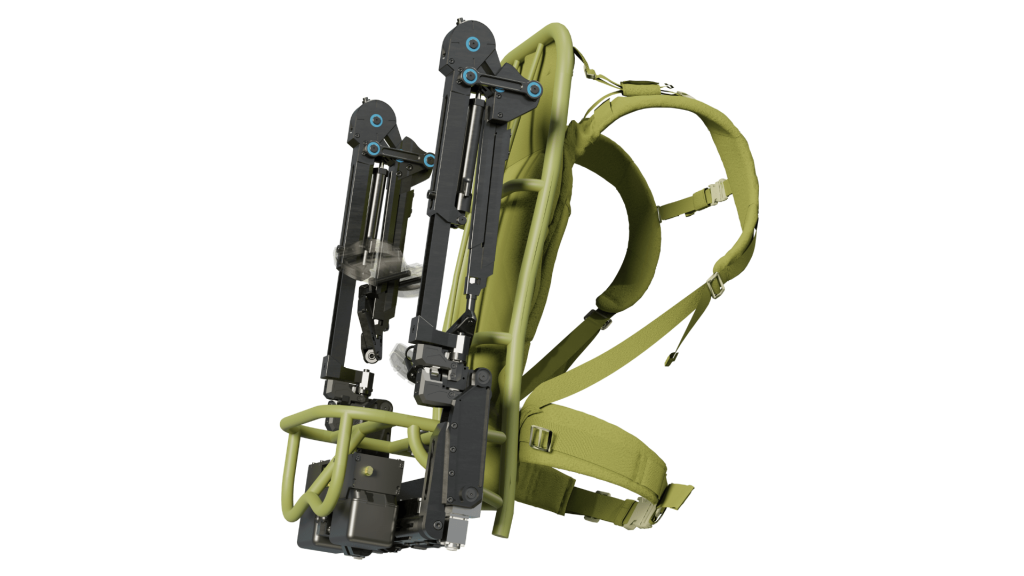

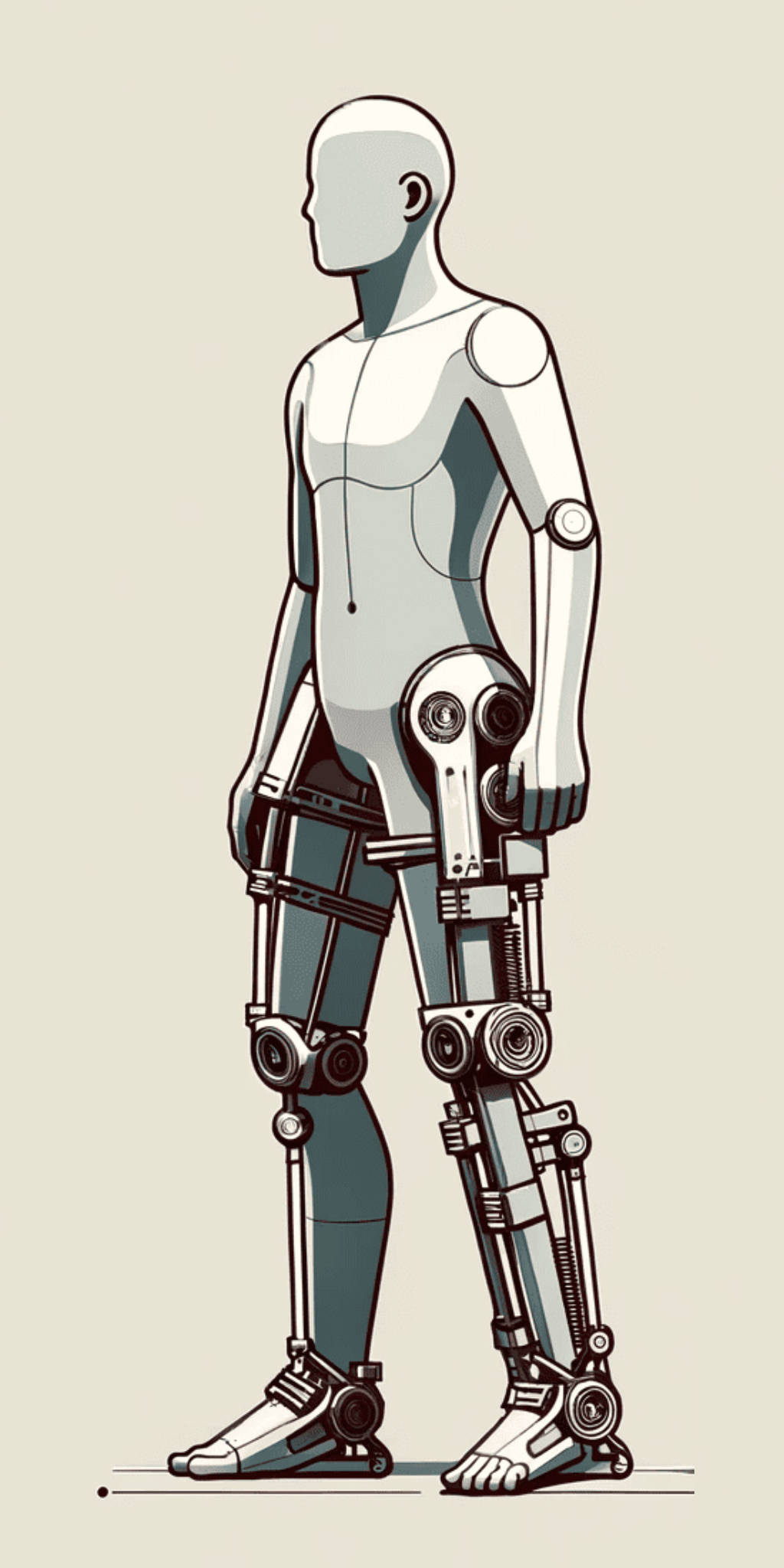

The Centaur is a light weight, semi-passive leg exoskeleton for transporting heavy equipment on foot.

our newest product:

see where we

can help you:

LIFTING AIDS

The core of our business is integrating springs for fast, powerful and safe mechanical solutions to aid humans in moving things, other humans or sometimes themselves.

Lifting aid applications can range from lifting a single fixed weight in the audio-visual or medical market like screens and monitors, or heavy enclosures in industry like for safe maintenance. To varying weights in the logistics in warehouses and distribution centres, or medically; patients of varying weights and body distributions.

By using spring systems these aids are untethered by powerlines, require minimal to no maintenance and can be used remotely and under demanding circumstances.

By using spring systems these aids are untethered by powerlines, require minimal to no maintenance and can be used remotely and under demanding circumstances.

Human & machine

Applying solutions in the human interactive domain required a deep understanding of human movement and the human body as a manipulator and controller.

Years of hands-on experience have equipped InteSpring with unique insights into human movement and ergonomics analysis. InteSpring uses a wide variety of available motions capture systems, databases and data-processing systems, as well as having developed a few of our own unique tools for modelling and simulation.

InteSpring designs and conducts human-in-the-loop laboratory and field experiments to validate our models, but also conducts customer research to validate the value proposition of your products.

InteSpring designs and conducts human-in-the-loop laboratory and field experiments to validate our models, but also conducts customer research to validate the value proposition of your products.

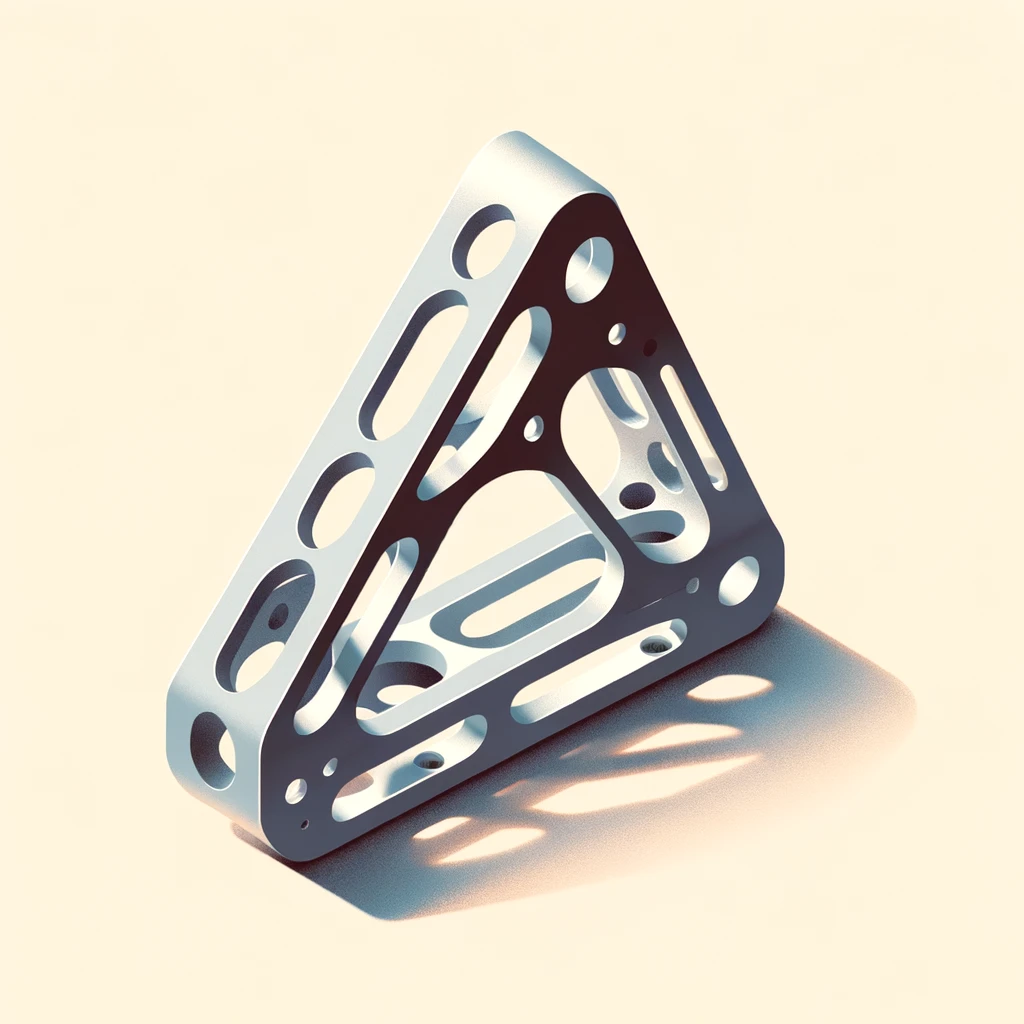

Compliant mechanisms significantly reduce the number of components and overall costs associated with spring mechanisms in suitable cases. They inherently exhibit less wear and thus introduce less failure modes.

Through involvement in several research projects in this field, InteSpring holds unique software and models to create these compliant spring components.

Through involvement in several research projects in this field, InteSpring holds unique software and models to create these compliant spring components.

compliant mechanisms

For the most demanding cost reduction and function integrated designs InteSpring designs special flexures or compliant cam mechanisms.

The medical product market requires a specialised ethos surrounding design documentation, certification and experience working together with licenced specialists and institutes. Although a lot of balancing technologies can find some use here, the added weight and responsibility of being certified as a medical device is often underestimated.

InteSpring has brought multiple certified products to market in this demanding field. Contact us to see how we can get your project into the hands of medical professionals and start helping patients.

InteSpring has brought multiple certified products to market in this demanding field. Contact us to see how we can get your project into the hands of medical professionals and start helping patients.

medical devices

Gravity-balancing and exoskeletons are closely related to orthotics and prosthetics but have many other uses in the operating room or healthcare in general.

Ridgid structures worn around the human body are referred to as exoskeletons. Exoskeletons become interesting when they augment the movement or force output of the wearer in some meaningful way. Most concepts in this space convince with their simplicity. Though this can be deceiving: InteSpring has had to learn to walk the difficult knife's edge between where to exert forces on the body to help, and most importantly, where not to apply forces to the body to avoid irritation and injury.

Where the complexities of human motion exceed the capabilities of simple mechanical systems, mechatronics and semi-passive systems come into play. Using sensoring and low-power actuation InteSpring can alter and adjust the function of the underlying passive systems we create, on the fly. This expands the use-case for an exoskeleton to a much more implementable tool for everyday use.

InteSpring creates exoskeletons under our own brands, we help develop standards with larger institutes and governments, and we help new entrepreneurs shape and market their own unique ideas.

Where the complexities of human motion exceed the capabilities of simple mechanical systems, mechatronics and semi-passive systems come into play. Using sensoring and low-power actuation InteSpring can alter and adjust the function of the underlying passive systems we create, on the fly. This expands the use-case for an exoskeleton to a much more implementable tool for everyday use.

InteSpring creates exoskeletons under our own brands, we help develop standards with larger institutes and governments, and we help new entrepreneurs shape and market their own unique ideas.

EXO-SKELETONS

Spring systems have proven themselves exceedingly adept in the wearable market, due to their untethered and safe nature.

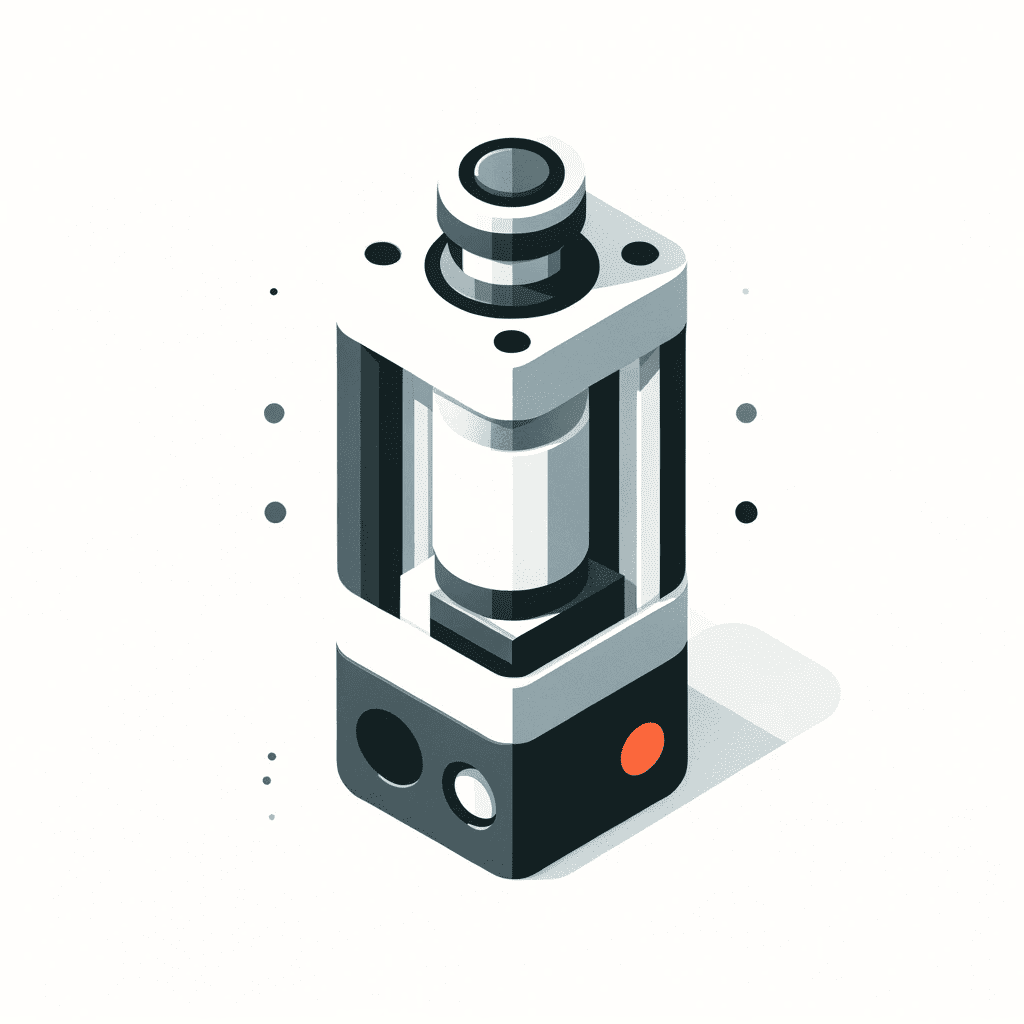

micro-hydraulics

For the most demanding circum-stances, where the most power and control are needed, InteSpring and its partners have developed a special range of microhydraulics.

The flow regimes and power outputs that are needed in human locomotion and manipulation are not in the standard industrial hydraulic range. That is why InteSpring and its partners have developed a special range of microhydraulics, specifically tailored to the wearable and exoskeleton market. This gives InteSpring a truly unique technology to implement to maximum effect in this field.

InteSprings microhydraulics are powerful, responsive and robust.

InteSprings microhydraulics are powerful, responsive and robust.

weight reduction

Implementing a multifaceted approach to weight reduction, using spring integration alongside precision engineering, topology optimisation or generative design.

The challenges posed by weight optimised design have led to innovative approaches in combining commercial Finite Element packages, Topology Optimizers and constrained design methods, with our own models and calculations. We use additive manufacturing, precision mechanics and a host of production techniques, wherever that is economically viable.

InteSpring not only helps clients make things weightless, but also helps by ensuring the solutions we offer are light weight themselves.

InteSpring not only helps clients make things weightless, but also helps by ensuring the solutions we offer are light weight themselves.

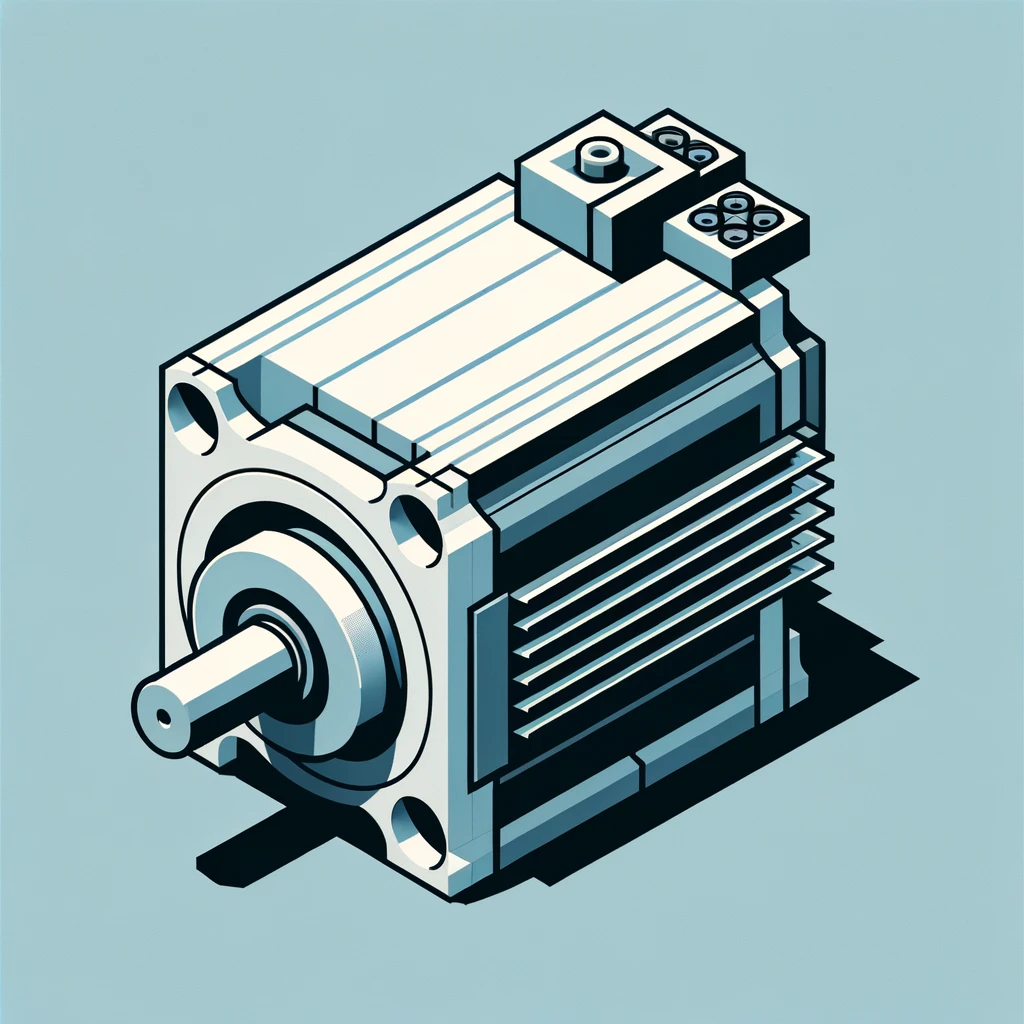

InteSpring implements mechatronics to adapt passive systems to dynamic environments. Creating hybrid mechanical-mechatronic systems benefitting from the flexibility of electronics and the simplicity of mechanics.

Low-power electronics can be used to change the weight of a balancing system to an exact amount, or aid in smoothing out some of the transition that some classical passive systems have.

Low-power electronics can be used to change the weight of a balancing system to an exact amount, or aid in smoothing out some of the transition that some classical passive systems have.

mecha-tronics

Sometimes the simplicity of spring-systems runs into the complexity of real life.

When the characteristics of passive systems need to change on the fly, due to changing circumstances or intent, sensoring and mechatronics can be used. Understanding how and when these characteristics have to change in a robust and seamless way is a task uniquely tailored to AI.

InteSpring integrates this tool into our most capable products, programming from the ground up with proprietary sensoring and printed circuitry. Analysing the diversity and complexity of human motion for maximum applicability.

InteSpring integrates this tool into our most capable products, programming from the ground up with proprietary sensoring and printed circuitry. Analysing the diversity and complexity of human motion for maximum applicability.

embedded ai

Artificial Intelligence has proven itself a powerful tool in human movement analysis and augmentation.

The YESDelft! environment and pedigree have uniquely positioned InteSpring to advise and guide other Start-ups and entrepreneurs, looking to develop A sustainable and profitable business.

InteSpring has special experience in the medical device and exoskeleton markets, with a solid supply chain of manufacturing partners, institutes for validation and capital for growth.

InteSpring has special experience in the medical device and exoskeleton markets, with a solid supply chain of manufacturing partners, institutes for validation and capital for growth.

startup mentorship

InteSpring was founded under the YESDelft! start-up incubator banner and has spun out numerous businesses with varying spring technologies at their core.

Integrating springs

REDUCE WEIGHT, INCREASE SPEED AND POWER WITH INTESPRING

Storage of mechanical energy can have many benefits. Springs are relatively light weight, can deliver large forces fast, and are incredibly durable.

InteSpring has extensive knowledge of mechanical spring systems, gas springs, hydraulic accumulator and damping systems, compliant structures, as well as magnetic springs. To implement these in more demanding tasks we are also proficient in mechatronics, sensoring and embedded programming and AI. All this knowledge can be combined with a variety of customizable positive and negative stiffness mechanisms.

Through their passive, low energy, and inherently safe characteristics these technical solutions lend themselves exceptionally well to the wearable and human interactive market. That is why InteSpring has expertise in human motion studies, movement analysis and modeling, as well as validation testing.

Finally there is a strong entrepreneurial spirit underlying the InteSpring team, having brought multiple technologies including medical devices and consumer goods to market under our own brands, or for select partners

InteSpring has extensive knowledge of mechanical spring systems, gas springs, hydraulic accumulator and damping systems, compliant structures, as well as magnetic springs. To implement these in more demanding tasks we are also proficient in mechatronics, sensoring and embedded programming and AI. All this knowledge can be combined with a variety of customizable positive and negative stiffness mechanisms.

Through their passive, low energy, and inherently safe characteristics these technical solutions lend themselves exceptionally well to the wearable and human interactive market. That is why InteSpring has expertise in human motion studies, movement analysis and modeling, as well as validation testing.

Finally there is a strong entrepreneurial spirit underlying the InteSpring team, having brought multiple technologies including medical devices and consumer goods to market under our own brands, or for select partners

Laevo

provides the healthiest way to prevent back pain in situations where you need to be mobile and can use immediate back support. InteSpring developed the technology behind Laevo.

Centaur

A light weight, semi-passive leg exoskeleton for transporting heavy equipment on foot. InteSpring is currently developing the Centaur for the Dutch Ministry of Defense.

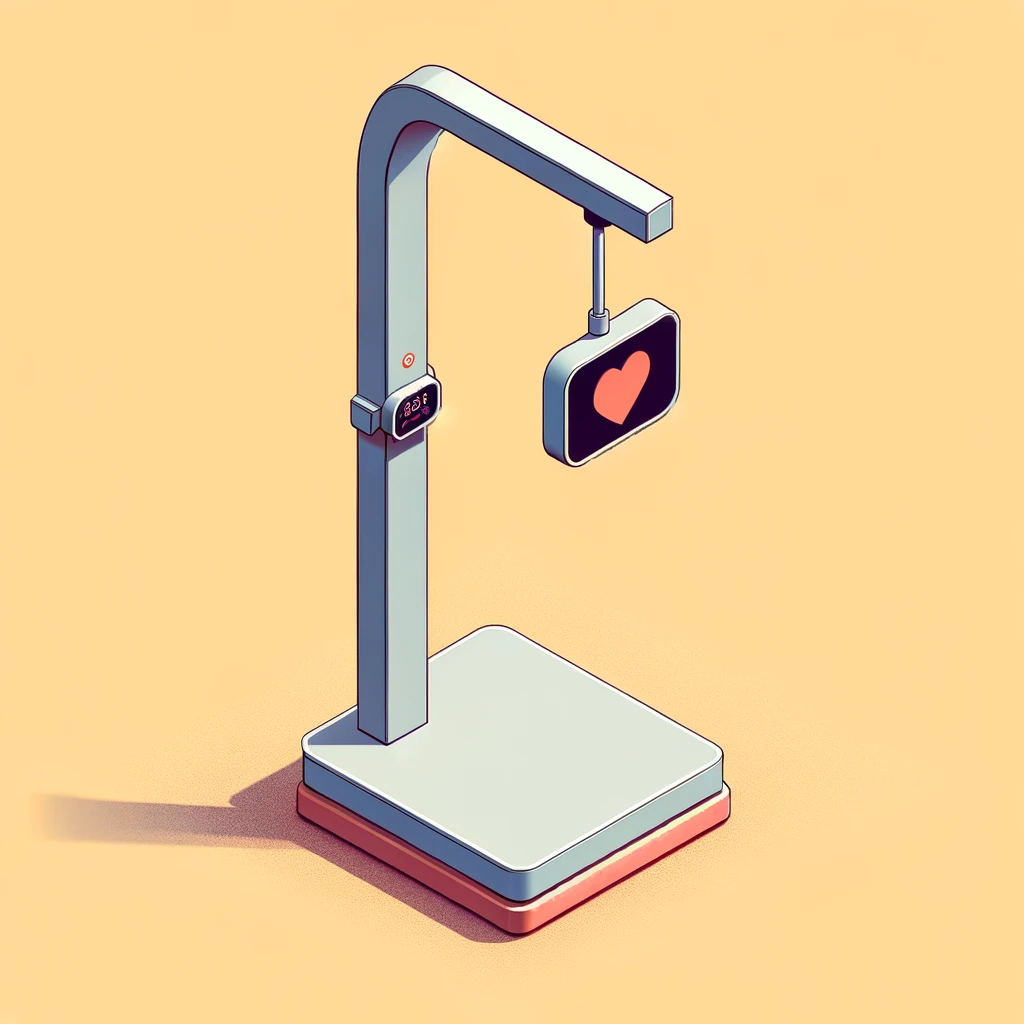

Skytron medical booms

InteSpring supported with the balancing; calculations, which components, mechanisms, and materials to use in the design of Skytron's most user-friendly booms.

Balancebox

Manually operated height adjustable mount based on a patented spring tension technology. Reliable, fast and user-friendly. InteSpring furnished the complete design of the product.

Hermes

A passive ankle orthosis for pes equinus which adds a negative stiffness around the ankle, giving the foot a natural position and regaining mobility of the joint.

InteSpring developed the Hermes together with the University of Leiden and OIM.

Enexis/ Zador enclosure

An all-weather enclosure with a unique balanced spring hinge system developed by InteSpring allowing access to its inner workings with the lift of a finger.

Laevo Back Exoskeleton

provides the healthiest way to prevent back pain in situations where you need to be mobile and can use immediate back support. InteSpring developed the technology behind Laevo.

See moreSkytron Medical Booms

InteSpring supported with the balancing; calculations, which components, mechanisms, and materials to use in the design of Skytron's most user-friendly booms.

See moreEnexis/ Zador enclosure

An all-weather enclosure with a unique balanced spring hinge system developed by InteSpring allowing access to its inner workings with the lift of a finger.

See moreCentaur Leg Exoskeleton

A light weight, semi-passive leg exoskeleton for transporting heavy equipment on foot. InteSpring is currently developing the Centaur for the Dutch Ministry of Defense.

See moreHermes Ankle Orthosis

A passive ankle orthosis for pes equinus which adds a negative stiffness around the ankle, giving the foot a natural position and regaining mobility of the joint.

InteSpring developed the Hermes together with the University of Leiden and OIM.

See moreBalancebox Adjustable Mount

Manually operated height adjustable mount based on a patented spring tension technology. Reliable, fast and user-friendly. InteSpring furnished the complete design of the product.

See more

Previous slide

Next slide

PORTFOLIO

Browse through a selection of our previous projects.

STORE SOME

ENERGY...

dive into

BALANCING...

INTESPRING's aproach

Our modular 4-phase consultancy system is built to maximize flexibility for adaptation to any project, minimizing risk for the client. Mix, match, and reshuffle phases to fit your R&D needs.

1. FEASABILITY

1.

FEASABILITY

The feasibility study delivers insights into the technical and economic viability of possible solutions.

2. DEMONSTRATOR

2.

DEMONSTRATOR

The design study provides technical solutions on component level detail.

3. DESIGN

3.

DESIGN

Production of a physical prototype is completed at high speed with our certified partners.

4. PRODUCT

4.

PRODUCT

We use our extensive network to set up a sustainable supply chain for series production.

see one of

our clients

cases

who is

intespring?

Follow in the footsteps